2025

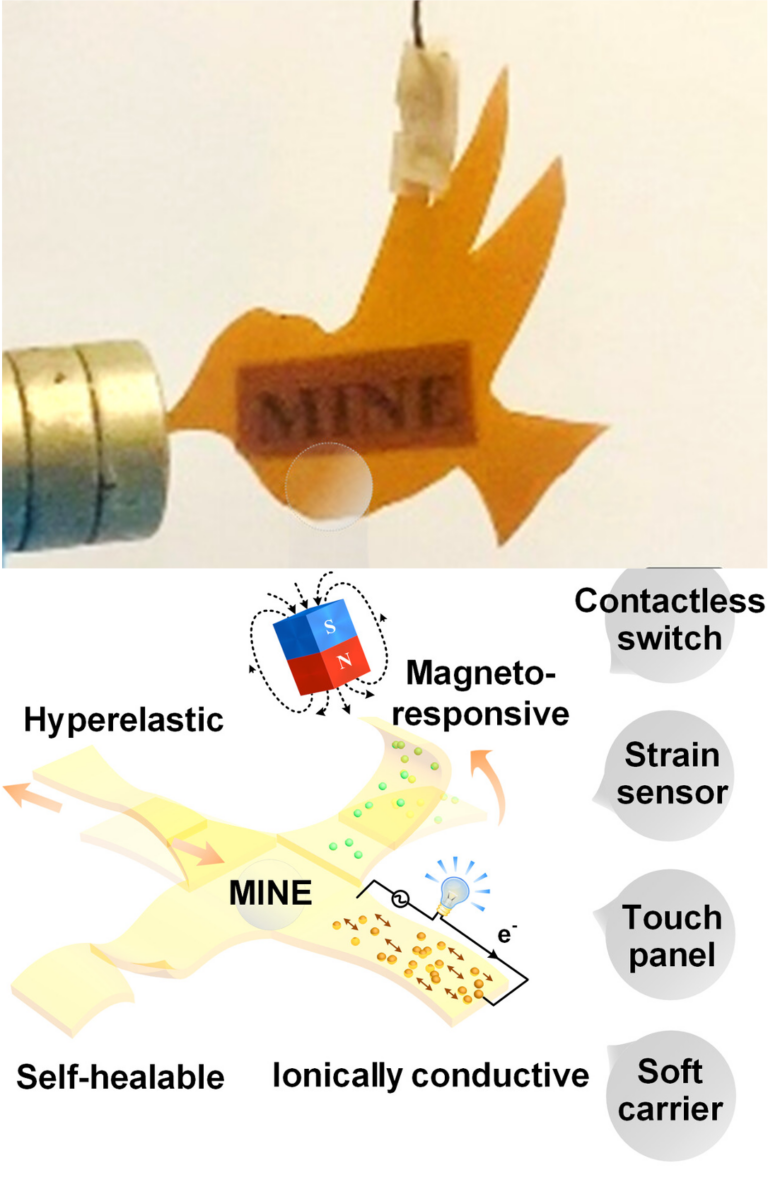

- Zhang X, Zhang L, Liu M, Chng CB, Pang EYL, Zhou J, Matsuhisa N, Tan YJ*. Self-healing and hyperelastic magneto-iono-elastomers through molecular confinement of magnetic anions. Sci. Adv. 2025; 11, eadq7441 link

- (invited) Zhou J, Wan J, Yu K, JS Ku, Tan YJ*. Unlocking Holistic Control of a Phototropic Liquid Crystal Polymer by Global Illumination. npj Robotics. 2025; 3, 7 link

- Recyclable self-secreting autonomous healing dielectrics for millisecond water quality sensing. Nat. Commun. Just accepted manuscript.

- (invited – Advanced Materials Rising Stars) 3D Printing of Auxetic Self-powered Mechanoluminescent Photonic Skins for Underwater Communication and Safety Monitoring. Adv. Mater. Just accepted manuscript.

2024

- Fu X, Wan G, Guo H, Kim HJ, Yang Z, Tan YJ, Ho JS, Tee BCK. Self-healing actuatable electroluminescent fibres. Nat. Commun. 2024; 15 (1), 1-10 link

- Ling S, Tian X, Zeng Q, Qin Z, Kurt SA, Tan YJ, Fuh JYH, Liu Z, Dickey MD, Ho JS, Tee BCK. Tension-driven three-dimensional printing of free-standing Field’s metal structures. Nat. Electron. 2024; 7, 671–683 link

- Li H, Chng CB, Zheng H, Wu MS, Bartolo PJDS, Qi HJ, Tan YJ*, Zhou K*. Self‐Healable and 4D Printable Hydrogel for Stretchable Electronics. Adv. Sci. 2024; 11, 2305702 (IF: 15.1) link

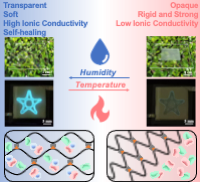

- Koh JJ, Zhang X, Ling S, Liu X, Zhou L, Qiao Z, Tan YJ*. A Smart Self‐Healing Material with Reversible Optical, Mechanical, and Electrical Transition Induced by Humidity and Temperature. Adv. Mater. Technol. 2024; 2400214 (IF: 6.8) link

- (Invited Perspective) Aracri S, et al., Tan YJ, et al. Soft Robotics: A Route to Equality, Diversity, and Inclusivity in Robotics. Soft Robot. 2024 (IF: 6.4) link

- Liu M, Li P, Tan YJ, Yang Z, See HH, Yang W, Liang FC, Cheng X, Tee BCK. An Extreme Environment Capable Self‐Healing Single Active Layered Triboelectric Sensors as Fully Recyclable and Transparent Human‐Machine Interfaces. Adv. Funct. Mater. 2024 link

2023

(Invited) Tan YJ, Mengaldo G, Laschi C. Artificial Muscles for Underwater Soft Robots: Materials and Their Interactions. Annu. Rev. Condens. Matter Phys. 2023; 15 (IF: 22.6) link

2022

Tan YJ. Harnessing the circular economy to develop sustainable soft robots. Sci. Robot. 2022; 7, eabn8147(IF: 27.54) link

- Anwar Ali HP, Zhao Z, Tan YJ, Yao W, Li Q, Tee BCK. Dynamic Modeling of Intrinsic Self-Healing Polymers Using Deep Learning. ACS Appl. Mater. Interfaces 2022; 14 (46), 52486-52498 (IF: 9.5) link

2021

- Tan YJ, Benjamin Tee CK. Recent trends in Self-Healing Soft Electronic Materials and Devices. Material Matters™, 2021, 16.3. link

Li H, Zheng H, Tan YJ, Tor SB, Zhou K. Development of an Ultrastretchable Double-Network Hydrogel for Flexible Strain Sensors. ACS Appl. Mater. Interfaces 2021. (IF:10.38) link

Li H, Tan YJ, Kiran R, Tor SB, Zhou K. Submerged and non-submerged 3D bioprinting approaches for the fabrication of complex structures with the hydrogel pair GelMA and alginate/methylcellulose. Addit. Manuf. 2021; 37: 101640 (IF: 11.63) link

Wang Z, Li X, Yang Z, Guo H, Tan YJ, Susanto GJ, Cheng W, Yang W, Tee BCK. Fully transient stretchable fruit‐based battery as safe and environmentally friendly power source for wearable electronics. Eco Mat 2021 (IF:12.21) link

- Zhao Y, Tan YJ, Yang W, Ling S, Yang Z, Teo JT, See HH, Kwok DHL, Lu D, Li S, Zeng X, Liu Z, Benjamin Tee CK. Scaling Metal-Elastomer Composites toward Stretchable Multi-Helical Conductive Paths for Robust Responsive Wearable Health Devices. Adv. Healthcare Mater. 2021. (IF: 11.09) link

2020

Tan YJ, Godaba H, Chen G, Tan MST, Li G, Lee PM, Cai Y, Li S, Shepherd RF, Ho JS, Benjamin Tee CK. A Transparent, Self-healing and High-κ Dielectric for Low-field-emission Stretchable Optoelectronics. Nat. Mater. 2020; 19: 182–188 (IF: 47.66) link

Highlighted on Nature Materials‘ News and Views: Nat. Mater. 2020; 19: 134–135

Tan YJ, Susanto GJ, Anwar Ali HP, Benjamin Tee CK. Progress and Roadmap for Intelligent Self-healing Materials in Autonomous Robotics. Adv. Mater. 2020; 2002800 (IF: 32.09) link

Guo H†, Tan YJ†, Chen G, Wang Z, Susanto GJ, See HH, Yang Z, Lim ZW, Yang L, Benjamin Tee CK. Artificially Innervated Self-healing Foams as Synthetic Piezo-Impedance Sensor Skins. Nat. Commun. 2020; 11 (1): 1-10 (IF: 17.69) link

Yao H†, Yang W†, Cheng W†, Tan YJ, See HH, Li S, Anwar Ali HP, Lim BZH, Liu Z, Benjamin Tee CK. Near Hysteresis-free Soft Tactile Electronic Skins for Wearables and Reliable Machine Learning. PNAS 2020; 117 (41): 25352-59. (IF: 12.78) link

Chen H, Koh JJ, Liu M, Li P, Fan X, Liu S, Yeo JCC, Tan YJ, Benjamin Tee CK, He C. Super Tough and Self-Healable Poly(dimethylsiloxane) Elastomer via Hydrogen Bonding Association and Its Applications as Triboelectric Nanogenerators. ACS Appl. Mater. Interfaces 2020; 12 (28): 31975-83. link

2019

- Cao Y†, Tan YJ†, Li S, Lee WW, Guo H, Wang C, Benjamin Tee CK. Self-healing electronic skins for aquatic environments. Nat. Electron. 2019;2: 75-82. (IF: 33.26) link

Featured as issue cover

Highly Cited Paper: top 1% citations of the academic field of Engineering in terms of Web of Science and 2019’s highly downloaded research in Engineering, Springer Nature

Highlighted on Nature Electronics‘ News and Views: Nat. Electron. 2019;2: 58-59

2. Lee WW, Tan YJ, Yao H, Li S, See HH, Matthew Hon, Ng KA, Betty Xiong, John Ho S, Benjamin Tee CK. A Neuro-inspired Artificial Peripheral Nervous System for Scalable Electronic Skins. Sci. Robot. 2019; eaax2198. (IF: 27.54) link

Featured as issue cover

3. Tian X†, Lee PM†, Tan YJ, Tina Wu LY, Yao H, Zhang M, Li Z, Ng KA, Benjamin Tee CK, John Ho S. Wireless Body Sensor Networks based on Metamaterial Textiles. Nat. Electron. 2019; 2: 243–251. (IF: 33.26) link

Featured as issue cover

Highlighted on Nature Electronics‘ News and Views: Nat. Electron. 2019; 2:217–218

4. Zhou M, Lee BH, Tan YJ, Tan LP. Microbial transglutaminase induced controlled crosslinking of gelatin methacryloyl to tailor rheological properties for 3D printing. Biofabrication 2019; 11: 025011. (IF: 9.954) link

5. Zhao Y, Yang W, Tan YJ, Li S, Zeng X, Liu Z, Benjamin Tee C.K. Highly conductive 3D metal-rubber composites for stretchable electronic applications. APL Mater. 2019; 7: 031508. (IF: 5.096) link

2018

Tan YJ, Wu J, Li H, Tee BCK. Self-Healing Electronic Materials for a Smart and Sustainable Future. ACS Appl. Mater. Interfaces 2018; 10: 15331–45. (IF: 10.38) link

Li H, Tan YJ, Li L. A strategy for strong interface bonding by 3D bioprinting of oppositely charged κ-carrageenan and gelatin hydrogels. Carbohydr. Polym. 2018; 198: 261-9. (IF: 10.72) link

Li H, Tan YJ, Liu S, Li L. Three-Dimensional Bioprinting of Oppositely Charged Hydrogels with Super Strong Interface Bonding. ACS Appl. Mater. Interfaces 2018; 10: 11164–74. link

Goh GL, Agarwala S, Tan YJ, Yeong WY. A Low Cost and Flexible Carbon Nanotube pH Sensor fabricated using Aerosol Jet Technology for Live Cell Applications. Sensor. Actuat. B Chem. 2018; 260:227–35. (IF: 9.22) link

Tan XP, Tan YJ, 3D and 4D Printing in Biomedical Applications: Process Engineering and Additive Manufacturing, Wiley-VCH Verlag GmbH & Co. KGaA, Weinheim, Germany, 2018, pp. 297–316. (Book chapter) link

2017

Tan XP†, Tan YJ†, Chow CSL, Tor SB, Yeong WY. Metallic powder-bed based 3D printing of cellular scaffolds for orthopaedic implants: A state-of-the-art review on manufacturing, topological design, mechanical properties and biocompatibility. Mater. Sci. Eng. C 2017; 76: 1328–43. (IF: 8.46) link

Li H, Tan YJ, Leong KF, Li L. 3D bioprinting of highly thixotropic alginate/methylcellulose hydrogel with strong interface bonding. ACS Appl. Mater. Interfaces 2017; 9: 20086–97. link

2016

Tan YJ*, Yeong WY, Tan XP, An J, Chian KS, Leong KF. Characterization, mechanical behavior and in vitro evaluation of a melt-drawn scaffold for esophageal tissue engineering. J. Mech. Behav. Biomed. Mater. 2016; 57: 246–59. (IF: 4.04) link

Tan YJ*, Tan XP, Yeong WY, Tor SB. Additive manufacturing of patient-customizable scaffolds for tubular tissues using the melt-drawing method. Materials 2016; 9: 893. (IF: 3.75) link

Tan YJ*, Tan XP, Yeong WY, Tor SB. Hybrid microscaffold-based 3D bioprinting of multi-cellular constructs with high compressive strength: A new biofabrication strategy. Sci. Rep. 2016; 6: 39140. (IF: 4.996) link

Tan XP, Kok Y, Toh WQ, Tan YJ, Descoins M, Mangelinck D, Tor SB, Leong KF, Chua CK. Revealing martensitic transformation and α/β interface evolution in electron beam melting three-dimensional-printed Ti-6Al-4V. Sci. Rep. 2016; 6: 26039. link

2015

Tan YJ*, Leong KF, An J, Chian KS, Tan XP, Yeong WY. Fabrication and in vitro analysis of tubular scaffolds by melt-drawing for esophageal tissue engineering. Mater. Lett. 2015; 159: 424–7. (IF: 3.57) link

Tan XP, Kok Y, Tan YJ, Descoins M, Mangelinck D, Tor SB, Leong KF, Chua CK. Graded microstructure and mechanical properties of additive manufactured Ti–6Al–4V via electron beam melting. Acta Mater. 2015; 97:1–16. link

Tan XP, Kok Y, Tan YJ, Vastola G, Pei QX, Zhang G, Zhang YW, Tor SB, Leong KF, Chua CK. An experimental and simulation study on build thickness dependent microstructure for electron beam melted Ti–6Al–4V. J. Alloys Compd. 2015; 646:303–9. link